JUMAG DG Series

High efficiency compact steam boiler

Oil or Gas Fired

JUMAG steam boilers combine the advantages of a compact quick steam boiler with those of a robust large capacity steam boiler.

-

Outputs from 100 kg/hr to 560kg/hr

-

Higher output as multiple unit system possible, e.g> 2000 kg/hr as four unit system

-

Oil or gas fired with standard industrial burners

-

Robust pressure vessel in the design of a small shell boiler, no coil.

-

Integrated boiler feed pump

-

Easy to operate, highly effective touch screen control - Connect to PC, mobile devices and BMS using JUMAG Connect

Economical

Robust and

low-maintenance

Operator Friendly

Adjustable manually via automatic timer or optional remote access controls

Good accessibility for maintenance

Automatic blowdown

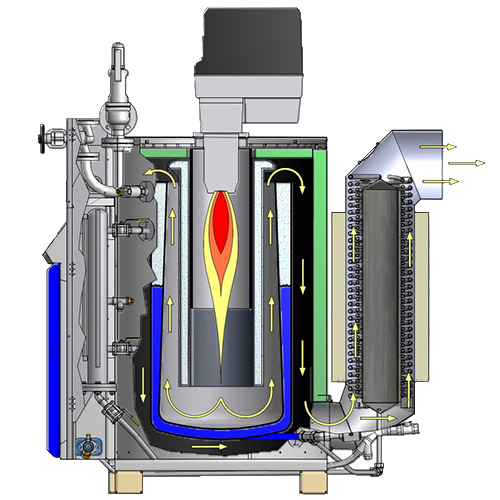

How it works

In contrast to the traditional steam generator, JUMAG steam boilers work as follows;

-

The feed water in the pressure vessel is topped up by the boiler pump through the economiser depending on the water level in the pressure vessel.

-

The burner is controlled depending on the steam pressure. Multi-pass flue gas routing transfers the heat from the flue gas through the pressure vessel to the water.

-

In the economiser, additional heat from the flue gas is transferred to the fresh water in the heat exchanger.

-

The steam is dried in the inner system of the pressure vessel.

Technical Data

| Boiler Type | DG160 | DG260 | DG360 | DG460 | DG560 |

| PED2014/68/EU Cat 3 |

|

|

|

|

|

| Steam output up to | 160 kg/hr | 260 kg/hr | 360 kg/hr | 46o kg/hr | 560 kg/hr |

| Heat Load |

|

|

|

|

|

| Heat Output |

|

|

|

|

|

| Max. Operating Pressure | 13.0 Bar | 13.0 Bar |

13.0 Bar |

13.0 Bar |

13.0 Bar |

| Working Pressure | 6 - 11 bar | 6 - 11 bar |

6 - 11 bar |

6 - 11 bar |

6 - 11 bar |

| Heat up time in mins | 5 minutes | 8 minutes |

8 minutes |

8 minutes |

8 minutes |

| Max Gas flow rate | 10.6 m3/hr | 16.9 m3/hr |

23.7 m3/hr |

30.4 m3/hr |

38.6 m3/hr |

| Power Supply | 400V / 50 Hz | 400V / 50 Hz |

400V / 50 Hz |

400V / 50 Hz |

400V / 50 Hz |

| Electrical Load | 2.4 kW | 3.2 kW | 3.2 kW | 4.0 kW | 4.0 kW |

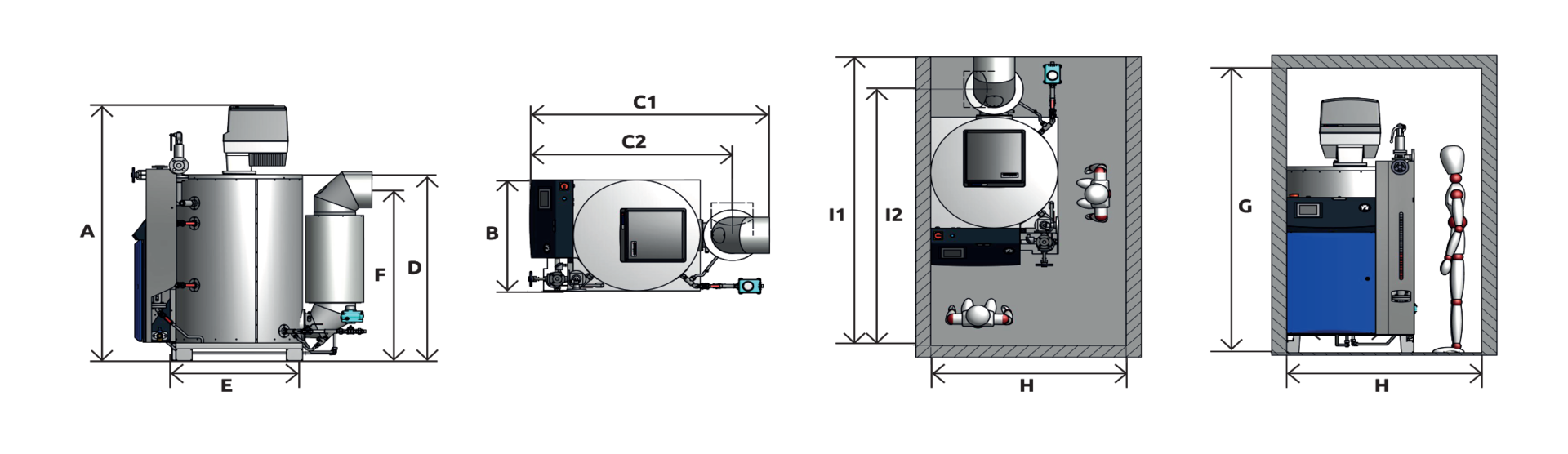

Dimensions*

| Boiler Type | DG160 | DG260 | DG360 | DG460 | DG560 |

| Total Height A | 1521 mm | 1764 mm | 2049 mm | 2044 mm | 2142 mm |

| Total width B | 815 mm | 829 mm | 829 mm | 936 mm | 936mm |

| Total depth C1 | 1411 mm | 1631 mm | 1631 mm | 1756 mm | 1756 mm |

| Total depth C2 | 1206 mm | 1370 mm | 1370 mm | 1484 mm | 1484 mm |

| Height D | 1130 mm | 1368 mm | 1568 mm | 1565 mm | 1565 mm |

| Depth E | 812 mm | 856 mm | 856 mm | 981 mm | 981 mm |

| Height F Flue Centre | 795 mm | 1437 mm |

|

|

|

| Min. operating height G | 1771 mm | 2014 mm | 2299 mm | 2294 mm | 2392 mm |

| Min. Operating Width H | 1315 mm | 1329 mm | 1329 mm | 1436 mm | 1436 mm |

| Min. Operating depth I1 | 2081 mm | 2301 mm | 2301 mm | 2426 mm | 2426 mm |

| Min. Operating depth I2 |

1876 mm | 2040 mm | 2040 mm | 2154 mm | 2154 mm |

* Dimensions for guide only : - Refer to specific dimensional drawings for installation